Dry Fertilizer & Liquid Agronomy Automation

New Dry Fertilizer Multi-Bin System With Orbital Mixer & Liquid Loadout Retrofit

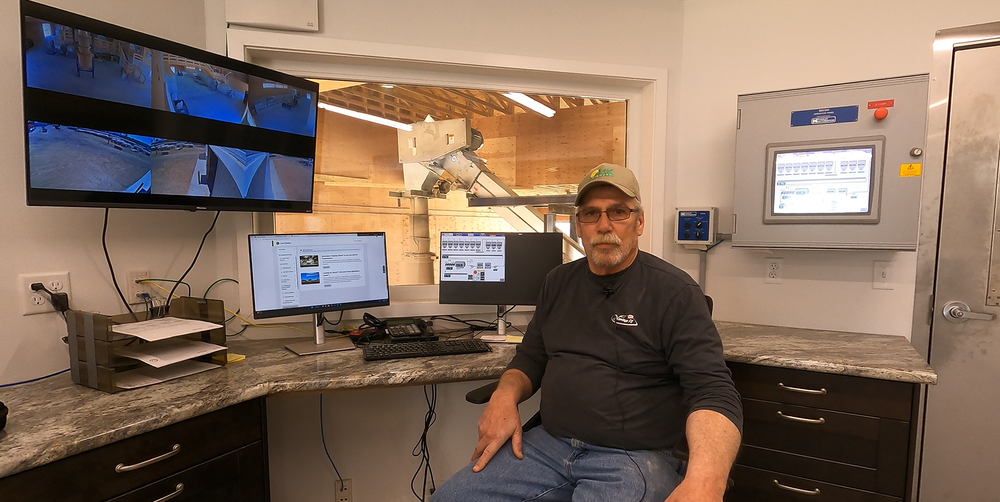

PROJECT: AgVantage FS, Mechanicsville, Iowa

OVERVIEW

From the new build to retrofit solution, AgVantage FS has enhanced the speed and efficiency of their dry and liquid loadout operations to meet current and future demand more effectively. The liquid system design features many process improvements that leverage our team’s knowledge, experience, and expertise. From hardware to software, the system has improved inventory accuracy, reducing shrinkage while providing more streamlined business management with expedited invoicing and reporting.

WHAT THEY NEEDED

AgVantage FS needed to update its dry and liquid agronomy center to handle both present demand and the future needs of customers. The company needed to update its inefficient dry fertilizer facility with a cost-effective solution to provide excellent blend quality and increased capacity. AgVantage FS also wanted to expand its offerings with additional dry products to provide a wider range of blend options for customers.

On the liquid side, AgVantage FS needed faster loadout and accuracy to match the pace of their applicators. The company needed a high-quality custom solution to maximize the efficiency of existing building design systems and avoid the need for a complete overhaul. Several aspects of the operation, including the repack process and billing, were inefficient and time-consuming. AgVantage FS needed to clearly understand inventory to help improve its business management and integration with Agvance.

WHAT WE DESIGNED

The initial project objective was construction of a new dry fertilizer building, with subsequent retrofit upgrades to the liquid fertilizer and crop protection building. We evaluated the facility’s overall cost of ownership and performance; we took into account both the liquid and dry components to provide seamless integration. The state-of-the-art dry facility supplies five different outlets in their region. The system is set up for 11 products plus swing products for precise blending. The motor control center with terminal nest offers quick and easy setup for onsite service.

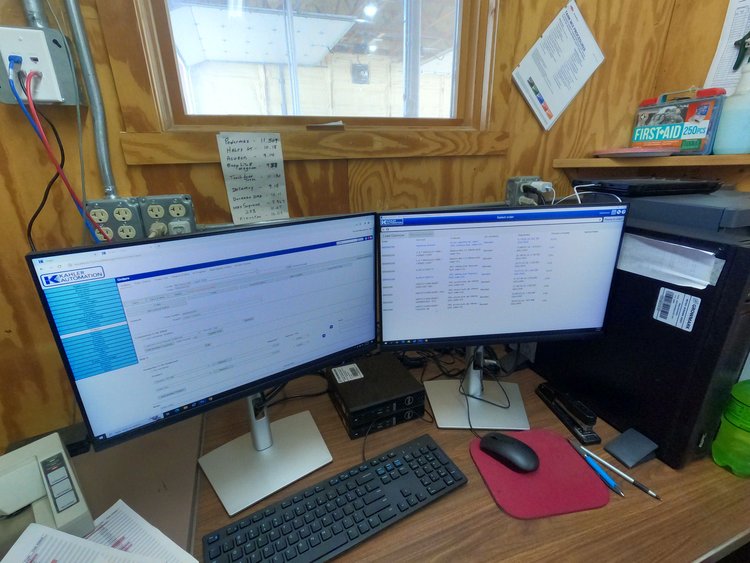

The liquid system features legal-for-trade mass flow meters for each chemical, so that everything can be run simultaneously to speed up loadout. Controls and software are common throughout this location, allowing for flexible staffing with more internal knowledge and easy product training. Electronic order integration provides a paperless process, eliminating manual entry errors for fast and accurate accounting.

Specs At A Glance

GENERAL

Business Name & Location: AgVantage FS in Mechanicsville, Iowa

Type of Business: Retail

Products Offered: Dry Fertilizer, Liquid Fertilizer, Crop Protection Chemicals

Total Acres: 2.4

Total Square Feet: 104,000

Receive Product Via: Truck

DRY FERTILIZER

Dry Fertilizer Storage Capacity: 8,330 tons

Number of Storage Bins: 6

Total Tons per Year: 12,600

Total Tons per Day: 250 to 300

Tons per Hour: 65

Receiving Capacity: 200 TPH

Loadout Capacity: 100 to 250 TPH

Blending Type: Orbital

Number of Materials in Typical Blend: 2-4

Micronutrients: 3

Impregnation: Yes, 2

Batch Sizes Offered: Any combination

Number of Trucks per Hour: 5

Truck Scale: Not required

Number of Operators Required: 1

Control System: Kahler Automation

LIQUID FERTILIZER & CROP PROTECTION

Liquid Fertilizer Storage Capacity: 120,000 gallons in 5 tanks

Type of Liquids Stored: 28% and Ammonium Thiosulfate (ATS)

Tonnage per Hour: 100

Number of Trucks per Hour: 6

Bulk Chemical Storage Capacity: 8 tanks, 8 totes for over 24,000 gallons

Loadout Capacity: Up to 400 GPM

Number of Operators Required: 1

Control System: Kahler Automation

WHAT THEY HAD TO SAY

Brad Newhard, Dry Shed Operator, AgVantage FS:

“We have spot-on loading, our weights come out right, our inventory comes out right. We can blend a lot more products. We only had two products before and now we have seven. Productivity is better than I ever expected.”

Angie Dusanek, Admin, AgVantage FS:

“Most of my job is billing for the chemical, seed, and fertilizer. With the old system … there was a lot of manual adding which ups the risk of counting errors and things like that. The new Kahler system … has made that quicker. The nice thing is it comes in automatically.”